Helicopter > Helicopter with Flettner double rotor

NC-2001 Abeille

NC-2001 Abeille, scale 1 : 4,8

From mid-2026 we will be adding the NC-2001 Abeille RC-helicopter with the Flettner double rotor system to our range. The faithful replica of the French civil helicopter from the 1940s. The model should therefore be an absolute rarity at flight days, which stands out from the replicas of modern helicopters.

The helicopter is constructed on a scale of 1 : 4.8 to the original NC-2001 Abeille and has a rotor diameter of 2.8 m.

The original was built in three different prototype versions. The first version will be offered first. Versions 2 and 3 will follow later.

Also in preparation are the true-to-original rotor blades in CFRP, which will further increase the scale optics of the original.

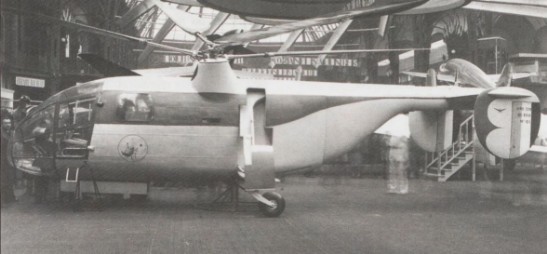

The NC-2001 Abeille, here the first of three manufactured prototypes. The simple rear main landing gear with the two large uncovered wheels is clearly visible. The two swashplates protrude from the fuselage cell and give the helicopter its unmistakable look

The second prototype with the faired rear wheels. You can see the curved rotor blades similar to a dragonfly

Kit NC-2001 Abeille

- Flettner mechanics, prepared for the Hacker Q80 electric motor: 4.095,- EUR

- Version with scale swashplates and drivers, swashplate holders with full ball bearings, special arrangement of the swashplate servos

- fuselage scale version, multi-part: price still open

- landing gear, scale version: price still open

- Microprocessor mixer electronics for controlling the two swash plates in the model (required to operate the model): 380,- EUR

- Kit without electric motor, controller, RC electronics, rotor blades, fuselage cell unpainted

On request we can offer you the following components to complete the helicopter:

- Carbon rotor blades 2.8 m rotor diameter, alternative

- Carbon rotor blades 2.8 m rotor diameter in scale optics (offered in the future)

- complete RC electronics

- Electric motor Hacker Q80 with controller and batteries

- painting of the model

- complete assembly of the kit, the RC electronics and the turbine. On request up to the ready-to-fly model

From the beginning of spring 2026, the newly introduced tectronic-in-motion flight controller will also be available, for easier and safer flight operation of large RC-model helicopters.

Zum Original, NC-2001 Abeille

The NC-2001 Abeille (English: Bee) was a single-engine twin-rotor helicopter designed and built in France in the late 1940s by SNCAC (Société Nationale de Constructions Aéronautiques du Centre). Three of these were completed in different designs, but only one flew and development ended when the SNCAC closed.

The design of the Abeille was led by René Dorand in SNCAC's helicopter department. Instead of a tail rotor design, an intermeshing rotor layout was chosen, following the 1939 Flettner Fl 265 and 1944 Kellet XR-8. Its twin, two-bladed rotors were driven by rotor shafts that protruded laterally at an angle of 12 degrees from the fuselage. The rotor blades had a very characteristic profile similar to dragonfly wings and tapered sharply to the end of the rotor blade.

Pitch and roll were adjusted from the control bar by changing cyclic pitch via a pair of swashplates and yaw by changing the relative collective pitch of the two rotors using the pedals. The forward tilt of the rotor shafts has been automatically linked to forward speed. A single lever controlled both collective pitch and throttle via an electrical linkage. The Abeille was powered by a 429 kW (575 hp) Renault 12S, an air-cooled V-12 engine.

The Abeille had a fuselage with a tail boom, designed as an all-metal hull. The nose was fully glazed with two seats side by side, in front of a cabin with a bench seat for three passengers. The engine and transmissions were located behind. The tailplane is located on top of the fuselage and had a pair of vertical stabilizer fins at its ends, each elliptical and mounted high up. For reasons of weight, these were made of wood and covered with fabric.

The fixed main landing gear of the first version of the Abeille had two wheels on a single axle positioned slightly aft of the rotor shafts and mounted along with a smaller nose wheel on wide single struts on the upper fuselage.

The second version had a similar chassis, but the two rear wheels were fitted with streamlined fairings. The suspension was also braced towards the fuselage.

The third version (NC-2002) had an elaborate retractable landing gear at the front and rear. The front wheel was folded backwards and the two rear wheels were folded sideways into the fuselage cell. In this version, the two swashplates were also completely covered.

Only three examples of the Abeille were built. The first was destroyed by fire before it had flown. The second made its first flight on June 28, 1949, piloted by Claude Dellys. However, SNCAC was shut down that month, its assets were divided among three remaining state-owned companies, and as a result the Abeille program was shut down. The second plane never flew again and the third never flew. (Translated from the English entry at Wikipedia)

The NC-2001 Abeille, here the second of a total of three prototypes made in different versions

The third prototype (type designation NC-2002) with the fully extended landing gear

Technische Daten NC-2001 Abeille, Original

- Besatzung: 2

- Passagiere: 3

- Triebwerk: 1 × Renault V12 Motor, wassergekühlt

- Leistung: 429 kW (575 PS) Startleistung

- Leergewicht: 2.064 kg

- Abfluggewicht max.: 2.694 kg

- Gesamtlänge Rumpfzelle: 9,7 m

- Rotordurchmesser: je 13,7 m

- Geschwindigkeit max.: 250 km/h

- Reisegeschwindigkeit: 180 km/h

Technische Daten NC-2001 Abeille, Modell im Maßstab 1 : 4,8

- Rotordurchmesser: 2,8 m

- Rotorwinkel: zwischen den beiden Rotorachsen 24°

- Länge über alles: 280 cm

- Rumplänge: 202 cm

- Rumpfbreite: 32 cm

- Breite über alles: 89 cm (Breite des Fahrwerks)

- Breite über die Leitwerke: xx cm

- Rumphöhe: 43 cm

- Höhe über alles: 70 cm

- Antrieb: elektrisch mittels Hacker Q80 (andere Antriebsmotoren auf Anfrage)

- Mechanik: robuster Industriestandard, komplett in Präzisions-CNC-Aluminium Fertigung und CFK

- Rotorkopf: 2 Stk. 2-Blattrotorköpfe, komplett in Aluminium, Blattlagerwelle 12 mm Durchmesser, Blattgriffe 22 mm

- Kraftübertragung: 2-stufiges Untersetzungsgetriebe, letzte Getriebstufe im Ölbad laufend

- Rotorkopfdrehzahl: ca. 800 1/min

- Taumelscheiben-Ansteuerung: 6 x Servos KST X20-3612 für die 3-Punkt-Anlenkungen der beiden Taumelscheiben, andere Servos auf Anfrage)

- FBL-System: alle handelsüblichen 3-Achs-Stabilisierungssysteme können integriert werden (z.B. Bavarian Demon 3X, Beast-X)

- Akkus: Lipo-Akkus, 12 S oder 14 S

- Abfluggewicht: ca. 25 kg

- Mischer: elektronischer Taumelscheibenmischer

- Mischfunktionen: Ansteuerung der beiden Taumelscheiben (120°-Mischer) für die Funktionen Pitch, Nicken, Rollen, Gieren

- Beleuchtung

- Antrieb mittels Verbrennungsmotor in Vorbereitung

Description of the Flettner mechanics NC-2001 Abeille

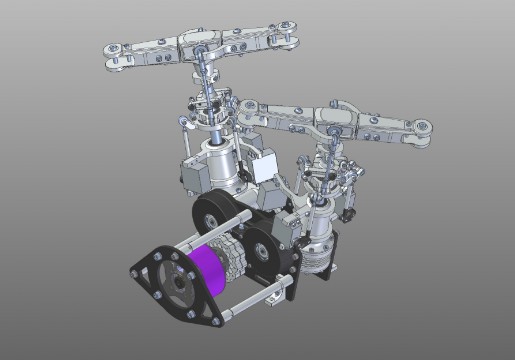

The complex mechanics of the model helicopter were developed entirely using 3D software. This is the only way to achieve the greatest possible planning security right from the start. All components are then manufactured based on the derived drawings and fit and function as planned right from the start.

In contrast to the Flettner mechanics of the K-Max 1200, the 3 servos for controlling the two swash plates are located directly above on the two gear domes. The power is transmitted directly to the special scale swashplates via short rods. The swash plate drivers are also a design specially developed for this model and, like the swash plate holder, have ball bearings.

For the drive: the Hacker Q-80 electric motor arranged in front of the mechanics transmits the power to the two main rotors via a 2-stage gearbox. The two rotors are coupled to each other via the middle pair of gears and are decoupled from the drive via a freewheel during autorotation.

Technical description:

- counter-rotating, intermeshing 2-blade double rotor system based on the Flettner principle

- very compact mechanics

- all CNC parts are made of aerospace aluminum (EN AW-7075 T6, black anodized) and carbon

- 2-stage reduction gear, last stage running in oil bath (completely encapsulated version)

- linkage of the two swashplates via 3 servos each, backlash-free 120° linkage

- scale swashplates

- the servos sit directly on the two rotor domes, linkage to the swashplate via short aluminum rods

- swashplate driver and swashplate holder each with 8 roller bearings

- all ball heads on the two swash plates and rotor heads are made of steel

- 65 roller bearings installed

- rotor shaft diameter 15 mm

- swashplate driver with full ball bearings

- blade bearing shaft diameter 12 mm

- rotor blade connection dimension 22 mm, 6 mm bore

- industrial quality finish

- detailed assembly and adjustment instructions

- assembly kit, assemblies that are difficult to assemble are supplied pre-assembled

View of the mechanics with the Hacker-Q80 electric motor, for reasons of center of gravity the motor is located in front of the mechanics

Some CAD images of the special mechanical design for the NC-2001 Abeille

Elektronic mixer for the NC-2001 Abeille

A special mixer electronics is required to control the two swash plates, which we also offer as an accessory. This electronics is connected in the model between the receiver and the swash plate servos. The advantages of such electronics are that important parameters can be changed quickly by changing the software. An associated programming module can be connected to the electronics in the model via a network cable. This can then be used to adjust all parameters in the workshop or on the airfield.

The model helicopter can be controlled like any other helicopter. Any normal remote control transmitter can be used as a transmitter without special mixers on the transmitter side.

A 3-axis flybarless system can also be easily integrated, see below.

The following functions are supported by the mixer electronics:

Processing of the signals for collectiv, roll, pitch and yaw from the receiver to control the two swashplates with 3 high-performance servos per swashplate, i.e. a total of 6 servos to control the two swashplates.

A stabilization system (e.g. Heli Command, V-Stabi, Beast-X etc.) or individual gyro systems (e.g. GY-401) for individual axes can also be looped in between the receiver outputs and the mixer electronics.

Alternatively, a Pixhawk 4 can also be used in the future. The special programming required to control the two swashplates is in preparation

Reprint only with permission of the author. All statements without guarantee.